Call: 08071932009

Experts in Truss Architecture, Truss Systems, Aluminium & Alloy Trusses, and Custom Truss Structures

- New Arrivals

- Featured

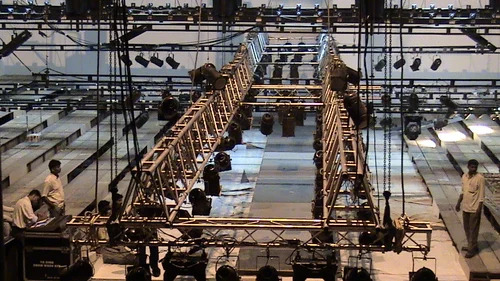

Shiv-Sung Truss LLP is a prominent manufacturer, supplier, and service

provider specializing in high-quality truss solutions. Established with

the vision of delivering durable, innovative, and efficient truss

systems, the company has emerged as a trusted name in the truss

architecture and construction sector. With years of expertise in

designing, fabricating, and supplying superior truss products, Shiv-Sung

Truss LLP caters to a wide array of industrial, commercial, and

event-related applications. Our commitment to quality, precision, and

customer satisfaction has positioned us as a preferred partner for

clients across diverse industries.

Shiv-Sung Truss LLP is committed to sustainable manufacturing practices. We focus on reducing waste, optimizing resource usage, and utilizing eco-friendly materials wherever possible. Our dedication to environmental responsibility complements our goal of delivering safe, durable, and high-performing truss solutions, ensuring that our operations contribute positively to the communities and industries we serve.

Commitment to Quality and Innovation

At Shiv-Sung Truss LLP, quality is not just a standard, it is a philosophy. We implement rigorous quality control measures at every stage of the manufacturing process to ensure our products meet international standards for strength, durability, and safety. Our team continually invests in research and development, adopting the latest technologies and materials to enhance the performance, reliability, and aesthetic appeal of our truss systems. This commitment to innovation allows us to offer cutting-edge solutions that address the evolving needs of our clients.

Client-Centric Approach

Our client-centric approach sets us apart in the industry. At Shiv-Sung Truss LLP, we believe in forging long-term partnerships with our clients by providing tailored solutions that meet their unique needs. Our experienced team of engineers, designers, and project managers works closely with clients from conceptualization to execution, ensuring seamless project delivery, timely completion, and exceptional after-sales support. We prioritize communication, transparency, and collaboration to ensure that every project not only meets but exceeds client expectations.

Vision and Mission

Our vision is to become a globally recognized leader in the truss manufacturing and supply sector by consistently delivering innovative, reliable, and sustainable solutions. Our mission is to provide high-quality truss systems that seamlessly combine functionality, aesthetic appeal, and structural integrity. By adhering to ethical business practices and promoting sustainable operations, we aim to create lasting value for our clients, partners, and stakeholders.

Manufacturing Unit

Our modern manufacturing unit and machinery allow Shiv-Sung Truss LLP to handle projects of any scale efficiently while maintaining superior quality and precision. The combination of advanced technology and skilled workforce ensures that every truss system delivered meets international standards and client expectations.

Machinery and Equipment

Shiv-Sung Truss LLP is committed to sustainable manufacturing practices. We focus on reducing waste, optimizing resource usage, and utilizing eco-friendly materials wherever possible. Our dedication to environmental responsibility complements our goal of delivering safe, durable, and high-performing truss solutions, ensuring that our operations contribute positively to the communities and industries we serve.

Commitment to Quality and Innovation

At Shiv-Sung Truss LLP, quality is not just a standard, it is a philosophy. We implement rigorous quality control measures at every stage of the manufacturing process to ensure our products meet international standards for strength, durability, and safety. Our team continually invests in research and development, adopting the latest technologies and materials to enhance the performance, reliability, and aesthetic appeal of our truss systems. This commitment to innovation allows us to offer cutting-edge solutions that address the evolving needs of our clients.

Client-Centric Approach

Our client-centric approach sets us apart in the industry. At Shiv-Sung Truss LLP, we believe in forging long-term partnerships with our clients by providing tailored solutions that meet their unique needs. Our experienced team of engineers, designers, and project managers works closely with clients from conceptualization to execution, ensuring seamless project delivery, timely completion, and exceptional after-sales support. We prioritize communication, transparency, and collaboration to ensure that every project not only meets but exceeds client expectations.

Vision and Mission

Our vision is to become a globally recognized leader in the truss manufacturing and supply sector by consistently delivering innovative, reliable, and sustainable solutions. Our mission is to provide high-quality truss systems that seamlessly combine functionality, aesthetic appeal, and structural integrity. By adhering to ethical business practices and promoting sustainable operations, we aim to create lasting value for our clients, partners, and stakeholders.

Manufacturing Unit

Our modern manufacturing unit and machinery allow Shiv-Sung Truss LLP to handle projects of any scale efficiently while maintaining superior quality and precision. The combination of advanced technology and skilled workforce ensures that every truss system delivered meets international standards and client expectations.

- Spacious Production Area: Our factory spans a large, well-organized area, allowing smooth workflow from raw material intake to finished product dispatch.

- Advanced Fabrication Sections: Dedicated zones for cutting, welding, assembly, and finishing ensure systematic production and maintain high-quality standards.

- Quality Control Lab: We have an in-house quality testing section where all products undergo rigorous inspection for strength, durability, and safety compliance.

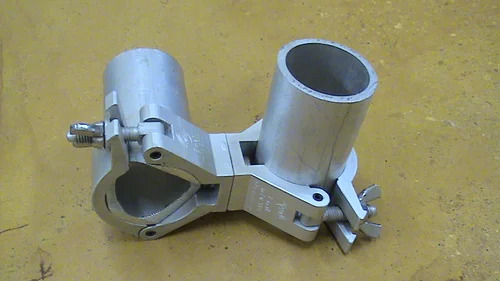

Machinery and Equipment

- CNC Cutting Machines: For precise cutting of aluminium and alloy components, ensuring accurate dimensions and clean edges.

- Welding Machines: MIG, TIG, and spot welding machines for creating strong and reliable joints in trusses and structures.

- Hydraulic Presses: Used for shaping, bending, and forming metal components to exact specifications.

- Pipe Bending Machines: For bending aluminium and alloy pipes to create custom truss shapes.

- Drilling and Punching Machines: Ensure accurate holes and fittings for easy assembly of truss systems.

- Powder Coating and Finishing Lines: Provide corrosion-resistant, high-quality finishes to enhance durability and aesthetics.

- Material Handling Equipment: Forklifts, cranes, and conveyors for safe and efficient movement of heavy components within the unit.

Back to top

Send Inquiry

Send Inquiry